Next exhibition-Indonesia 32nd manufacturing machinery

November 20, 2023

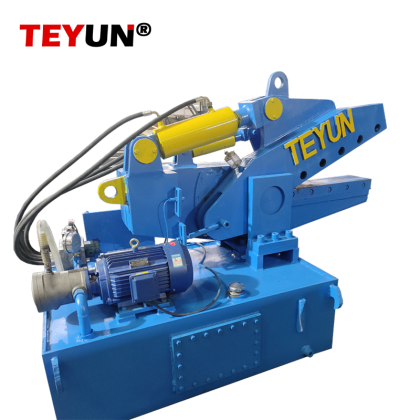

The 32nd International Manufacturing Machinery, Equipment, Materials and Service Exhibition,TEYUN is here: Booth:A1-136 Date: 6th~9th, Dec. Add:Jakarta International Expo Kemayoran This exhibition is the third exhibition for TEYUN to attend in this year, this means TEYUN attaches great importance to overseas markets, and is committed to expand overseas markets to serve the local customers. TEYUN products fit the theme of this exhibition very much, so we bring our hot sale products to the In donesia market. Teyun has specilized in the hydraulic machines for over 20 years, and mainly in two parts, one is the recycling equipment including the baler(metal baler, horizontal baler, vertical baler), briquette press, scrap metal shear(alligator shear, container shear, gantry shear, tiger shear) and the shredding machine; another part is the metal extruder including the aluminum extrusion press, cooper/magnesium extrusion press and ect. Teyun has exported to many countries for many years and always adhere to “be pragmatic, innovative, pioneering and enterprising". Teyun has a professional sales team to serve the oversea markets customers, with professional technical support,skilled language communication and 24*7 after-sale service. So if you are interested in TEYUN products, pls contact us we can offer you the whole line solutions. You can contact us via the mail: info@njteyun.com, or our hot line:+86 13566045899(whatsapp).

Read More

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

November 20, 2023

November 20, 2023

IPv6 network supported

IPv6 network supported