Teyun

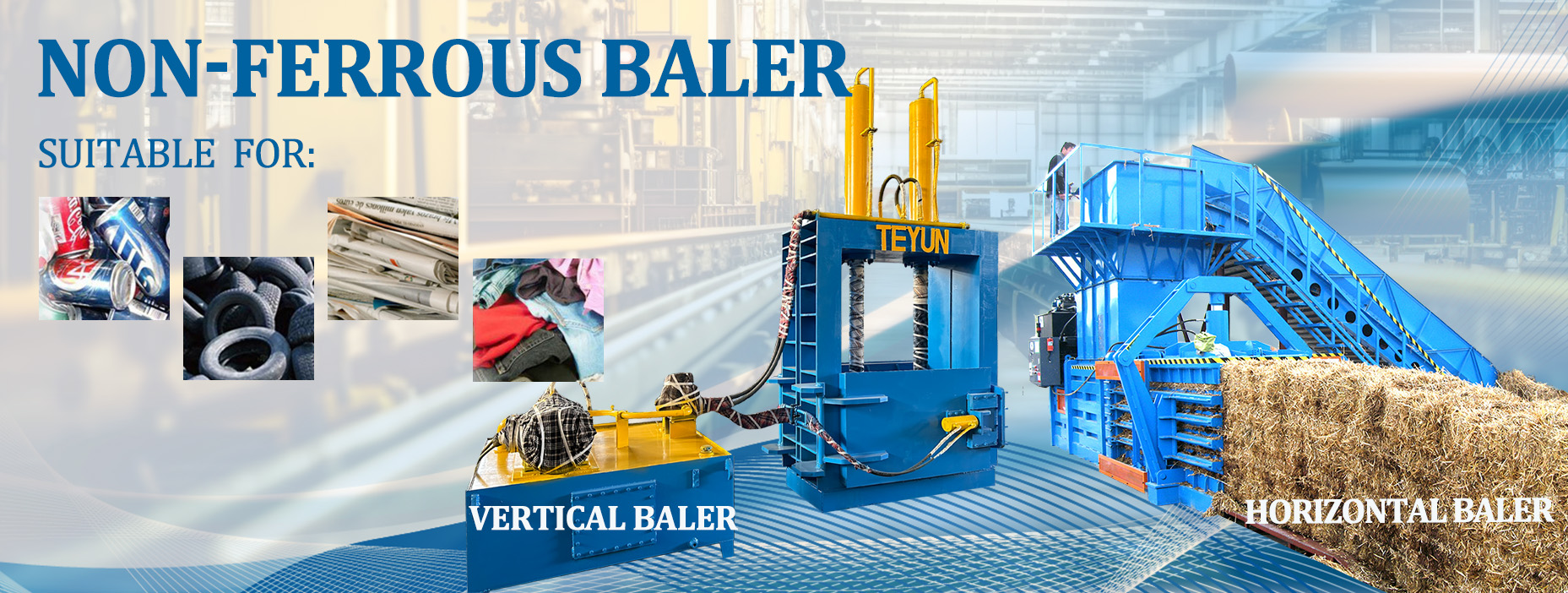

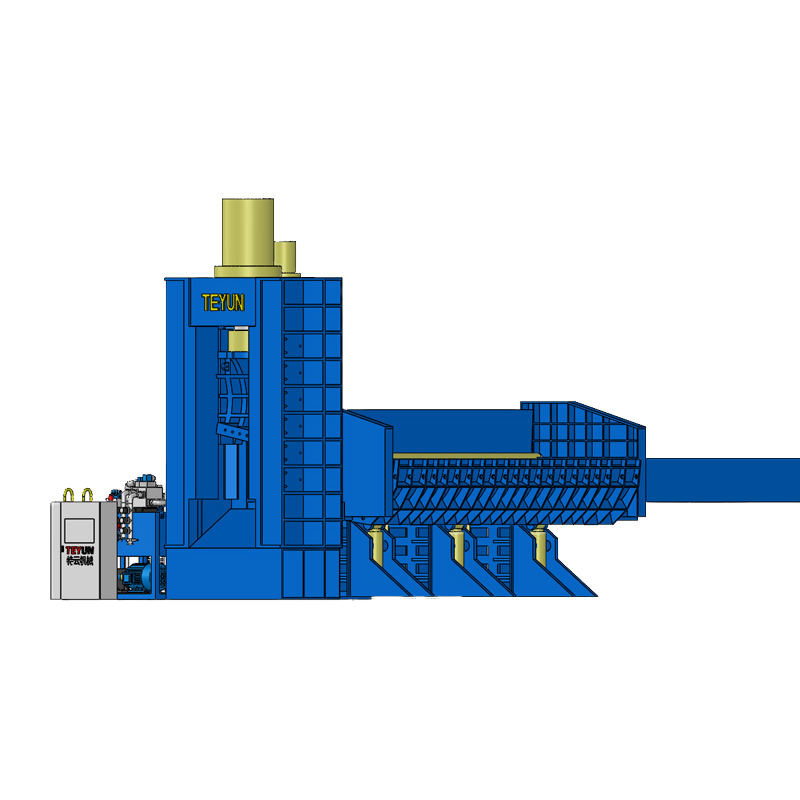

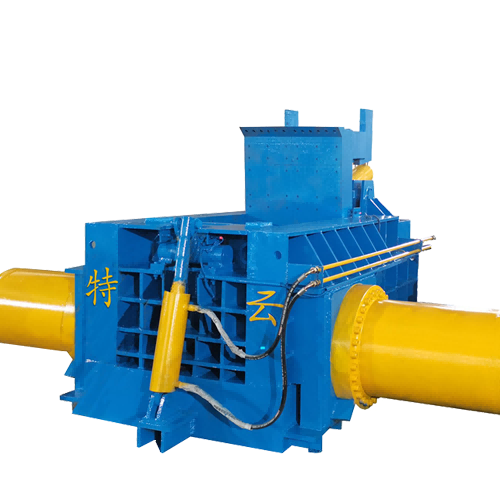

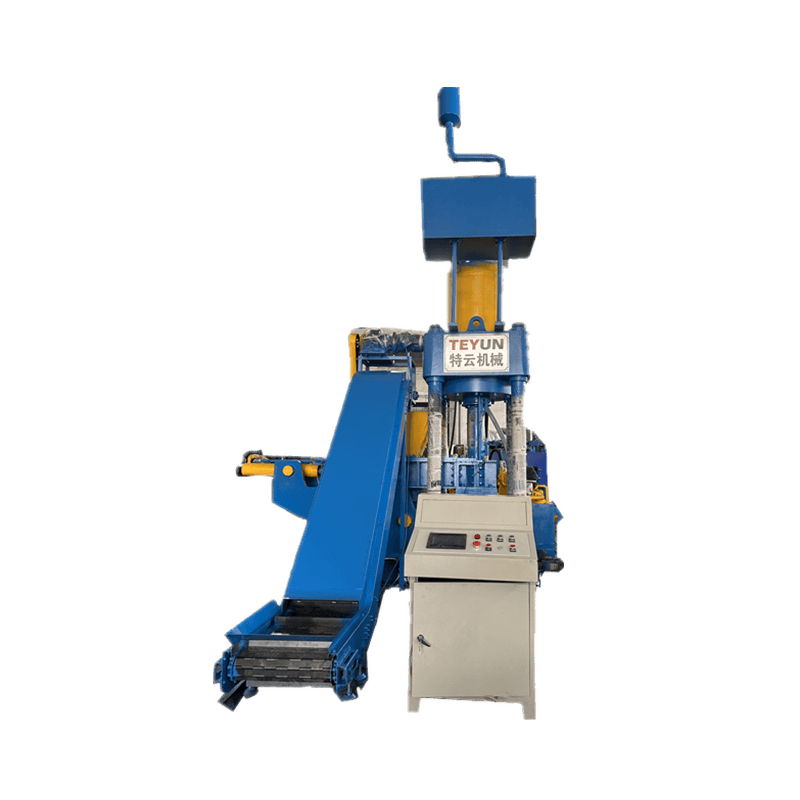

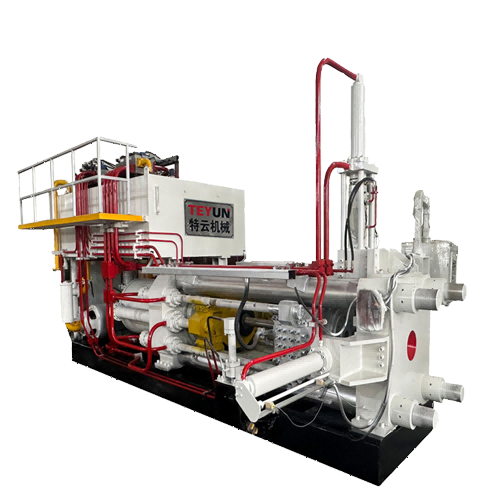

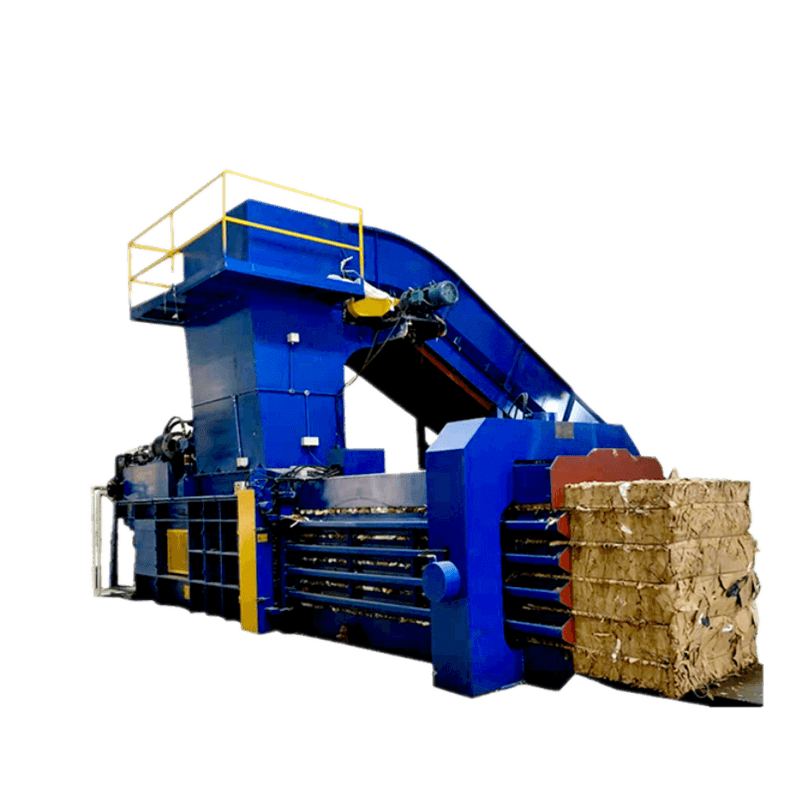

Teyun was founded in 1997 and has a history of more than 20 years. Teyun is a professional manufacturing enterprise with many years experience in designing and manufacturing hydraulic machine. It is a key enterprise that produces various hydraulic equipment and metal mechanical equipment in China with strong technical force, advanced production equipment and complete testing methods. Leading products include TY81 series metal hydraulic baler, TY43 series alligator hydraulic shearing machine, TY15 series gantry shearing machine, TY83 series hydraulic scrap baling machine, TYPM automatic waste paper baling machine and so on. We always adhere to “be pragmatic, innovative, pioneering and enterprising". With rich experience in designing and good capabilities of equipment processing and manufacturing, we can design and manufacture various non-standard hydraulic machinery according to the special requirements selected by customers. In China, we serve major waste recycling companies, large steel mills, sanitation systems, etc., providing customers with complete solutions. Our products are exported to Japan, Russia, Australia, the United States, the United Kingdom, Germany, and other countries and regions. Our high-quality performance and service have won the recognition and repurchase of overseas buyers. At the same time, in some countries, we have set up brand agents to serve local countries. We sincerely welcome you to join our agency team and start a pleasant cooperation.

Nanjing Teyun Machinery Manufacture Co., Ltd. was founded in 2010 and has a history of more than 10 years. Teyun is a professional manufacturing enterprise with many years experience in designing and manufacturing hydraulic machine. It is a key enterprise that produces various hydraulic equipment and metal mechanical equipment in China with strong technical force, advanced production equipment and complete testing methods. Leading products include TY81,TY83,TYPM series metal hydraulic baler, TY43 series alligator hydraulic shearing machine,TY15 series gantry shearing machine and so on. We always keep “be pragmatic, innovative, pioneering and enterprising". With rich experience in designing and good capabilities of equipment processing and manufacturing, we can design and manufacture various non-standard hydraulic machinery according to the special requirements selected by customers. We become one of the most promising domestic manufacturing enterprises which produces hydraulic machine such as balers, shearing machines, and hydraulic scrap machine, and have a huge influence on the waste recycling equipment industry.

View more about

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported