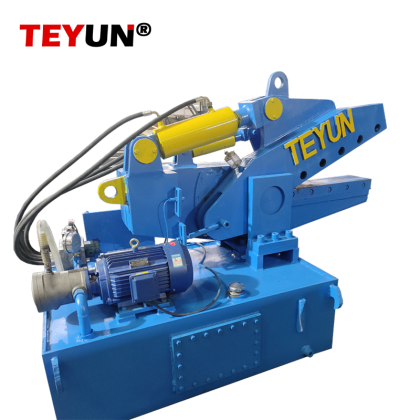

In the bustling world of scrap yards, demolition sites, and recycling facilities, a powerful and specialized tool reigns supreme: the metal container shear. Attached to the arm of an excavator, this hydraulic marvel is far more than just oversized scissors; it's an essential engine driving efficiency and safety in processing massive metal structures, particularly ubiquitous shipping containers.

The core function is brutally simple yet incredibly effective: to cut through thick steel with immense, controlled force. Hydraulic pistons generate tremendous pressure, driving specially hardened, often replaceable blades together. These blades are designed not just for sharpness, but for incredible strength to overcome the high tensile strength of steel used in containers, trucks, and industrial structures. Unlike shredders that pulverize, shears cleanly sever metal, creating manageable pieces.

This cutting action unlocks critical functions:

1. Size Reduction: Intact shipping containers or large metal structures are bulky and inefficient to transport or process. Shears rapidly slice them into smaller, more manageable sections (often "flattening" them), drastically increasing the volume that fits onto trucks heading to steel mills.

2. Material Liberation: Shearing cuts through structural members, freeing different metals (like steel walls from aluminum corner castings) and separating contaminants (wood floors, insulation) for more efficient downstream sorting and higher-quality scrap streams.

3. Controlled Demolition: On demolition sites, shears provide precise cutting power to dismantle metal frameworks, storage tanks, and machinery safely from a distance, minimizing risks associated with manual cutting or explosive methods.

4. Efficiency & Cost Savings: By processing metal rapidly on-site, shears significantly reduce handling time, labor costs, and transportation expenses compared to moving whole, cumbersome structures. They maximize the value extracted from scrap metal.

5. Safety Enhancement: Operators work from the protected cab of an excavator, directing the shear's power remotely. This greatly reduces exposure to hazards like flying debris, sharp edges, structural collapses, or sparks associated with torches.

The metal container shear is more than just a cutting tool; it's a productivity multiplier and a safety sentinel in heavy industries. By transforming unwieldy steel giants into compact, processable scrap, it plays a fundamental role in the circular economy, ensuring valuable metal resources are efficiently recovered and returned to the production cycle, one powerful, clean cut at a time.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported