Tires baler for recycling the car tires, truck tires

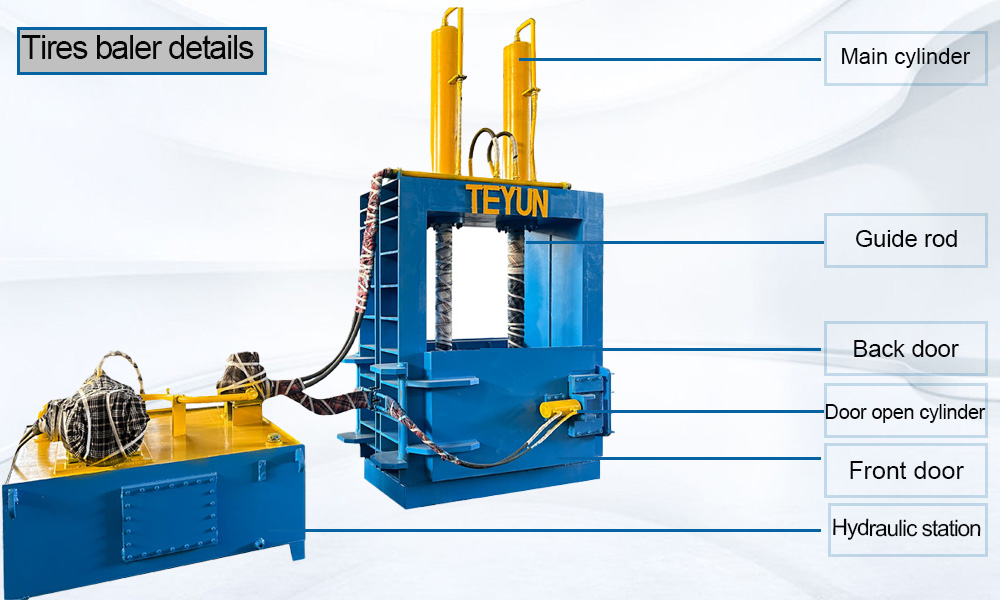

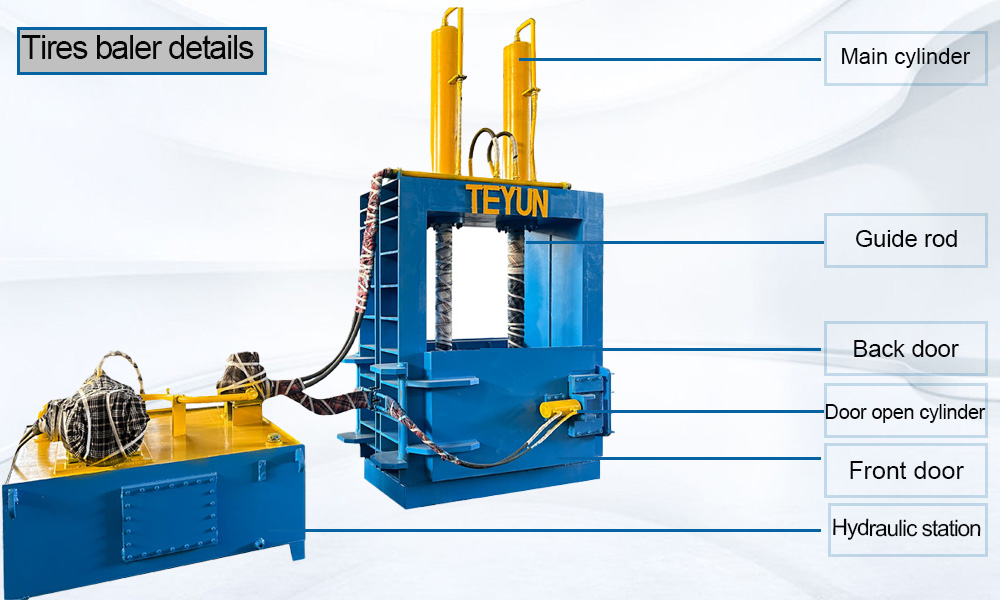

Tires Baler Introduction:

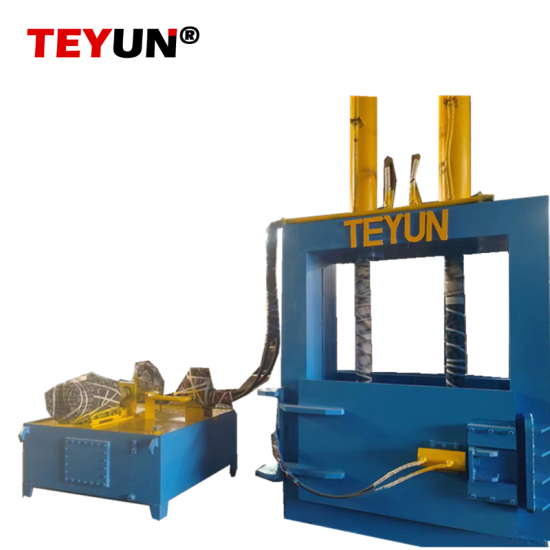

The tires baler is especially designed for baling the waste car tires, truck tires, bus tires and ect. This tires baler can help to reduce the waste of the tires for second use. The baling process of the tires compress the waste tires into a bale, can reduce the shipping cost of the waste tires and aslo save the tires stock space. So the tires baler is a popular equipment in the tires recycling industry.

Tires Baler Features:

- Easy and and safety operation with manual control

- Simple maintainance

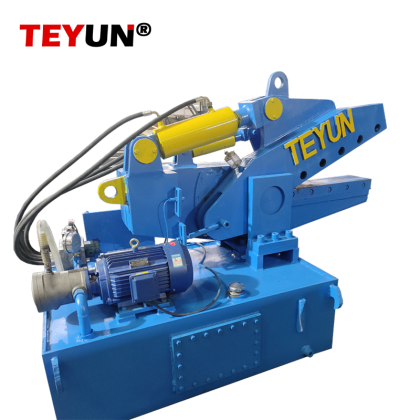

- Hydraulic-driven opening door

- Electrical part: Siemens

- CE,ISO,SGS,TUV certifactes

Working process of the tires baler:

Tires Baler Parameters:

| Item |

TY82-160 |

TY82-180 |

|

Main Press Force

|

80ton*2=160Ton

|

60ton*3=180Ton

|

|

Feeding Opening(L*W)

|

1530*600mm

|

1600*600mm

|

|

Compression Chamber Size(L*W*H)

|

1530*790*1600mm

|

1600*790*1600mm

|

|

Bale Size(L*W*H)

|

1530*790*(300-1000)mm

|

1600*790*(300-1000)mm

|

|

Bale Size (after expansion) (L*W*H)

|

1530*790*1000mm

|

1600*790*1000mm

|

|

Bale Weight

|

1 ton

|

1.2 ton

|

|

Production Rate

|

1~2tons/h

|

1~2tons/h

|

|

Operation System

|

Electric Control Valve

|

Electric Control Valve

|

|

Locking System

|

Front Door and Back door With Locking Cylinder

|

|

Machine weight

|

9 tons

|

10 tons |

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported