The Silent Giants of Sustainability: How Metal Briquetting Machines are Reshaping Industry

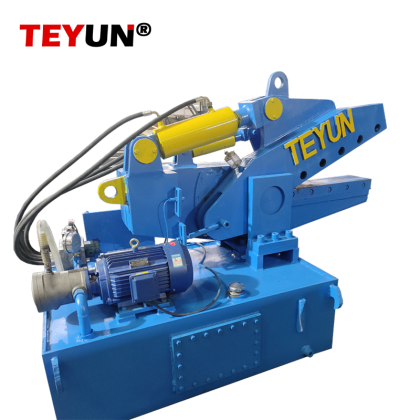

In the bustling heart of modern industry, where efficiency and sustainability are no longer ideals but necessities, a powerful yet often overlooked machine is making a profound impact: the metal briquetting machine. These robust pieces of equipment are the cornerstone of a circular economy for metals, transforming what was once considered messy, hazardous, and low-value waste into a clean, profitable, and reusable resource. At its core, a metal briquetting machine is a hydraulic press that applies immense pressure to loose metal scraps—often referred to as "swarf" or "turnings"—and compacts them into dense, uniform blocks known as briquettes. This simple act of compression is a game-changer. The raw material, which can range from aluminum and copper to steel, cast iron, and even titanium, is typically generated in vast quantities by machining operations like milling, turning, and drilling. In its loose form, this scrap is problematic. It takes up valuable floor space, poses safety hazards due to sharp edges, can be a fire risk when saturated with flammable cutting fluids, and is inefficient and costly to transport. The briquetting process elegantly solves these challenges. By compressing the material, these machines achieve a dramatic volume reduction, often by a factor of 10:1 or more. This immediately frees up factory space, simplifying housekeeping and improving the overall work environment. The resulting briquettes are dry, solid, and easy to handle. They can be stacked neatly on pallets, stored safely outdoors, and transported with standard logistics, drastically reducing haulage costs. However, the benefits extend far beyond mere convenience. The economic and environmental advantages are substantial. From Cost Center to Revenue Stream For manufacturing facilities, metal scrap was traditionally a cost—money had to be spent on its collection, handling, and disposal. A briquetting machine flips this model. By converting scrap into high-density briquettes, the material becomes a highly desirable commodity for metal recyclers and foundries. Briquettes are more efficient to melt in furnaces because of their high mass-to-surface-area ratio, leading to less oxidation and metal loss (yield). Consequently, recyclers pay a premium price for briquetted metal compared to loose, oily turnings. This transforms a waste stream into a significant source of secondary income, often providing a rapid return on investment for the briquetting machine itself. A Pillar of Green Manufacturing In an era of heightened environmental awareness, briquetting is a clear win for sustainability. First, it promotes the recycling of valuable raw materials, reducing the need for energy-intensive primary metal production. Recycling aluminum, for instance, requires only about 5% of the energy needed to produce it from ore. Second, many modern briquetting systems incorporate an integral extraction process that sque...

Read More

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported