Scrap Metal Balers: Essential Machines for Efficient Recycling

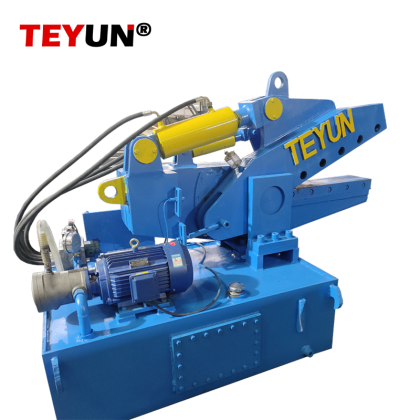

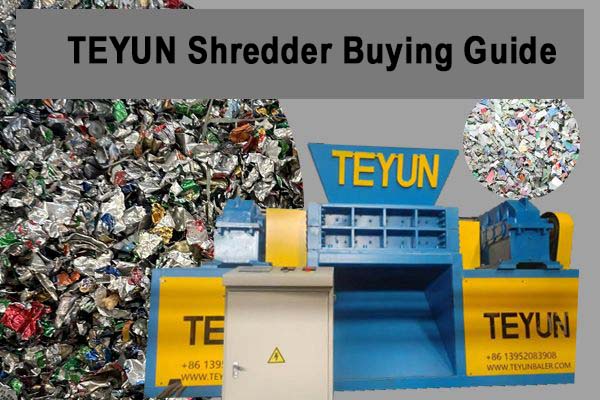

The metal baler is a cornerstone of the scrap metal industry, transforming loose, bulky, and hazardous scrap into dense, uniform bales. This hydraulic press uses immense force to compress materials like steel, aluminum, and copper, delivering three key benefits: significant volume reduction, enhanced product value, and improved workplace safety. A scrap metal baler is designed to compress and bundle various types of scrap metal into compact, dense bales for easier handling, transportation, and recycling. The operational process is straightforward. Scrap is loaded into a charging box, where a powerful hydraulic ram compresses it. Once a pre-set density is achieved, the finished bale is ejected, ready for shipment.These machines play a crucial role in the metal recycling industry by optimizing storage space, reducing logistical costs, and improving the efficiency of processing scrap materials. Economically, it slashes transportation and storage costs while creating a standardized product that commands higher prices from mills. Operationally, it streamlines material flow and reduces the required storage footprint. Furthermore, it greatly enhances safety by consolidating sharp, loose materials and helps contain fire hazards. How Scrap Metal Balers Work Scrap metal balers operate using hydraulic pressure to crush and compact loose metal scraps—such as aluminum cans, steel sheets, copper wires, and automotive parts—into uniform bales. The process typically involves: 1. Feeding: Scrap metal is loaded into the baler’s chamber, either manually or via conveyor systems. 2. Compression: A hydraulic ram applies extreme pressure (ranging from dozens to hundreds of tons) to compress the metal. 3. Binding: The compacted metal is secured with wires or straps to maintain its shape. 4. Ejection: The finished bale is discharged for storage or shipment. Types of Scrap Metal Balers 1. Vertical Balers: Smaller and more affordable, ideal for low-volume operations (e.g., recycling centers or workshops). 2. Horizontal Balers: Heavy-duty machines for large-scale recycling plants, offering higher throughput and automation. 3. Two-Ram Balers: Advanced systems with dual rams for superior density, often used for ferrous metals like steel. 4. Mobile Balers: Mounted on trucks for on-site processing at demolition sites or scrapyards. Key Benefits · Space Efficiency: Bales occupy up to 90% less space than loose scrap. · Cost Savings: Reduces transportation and storage expenses. · Environmental Impact: Promotes recycling by making scrap easier to process for smelters. · Safety: Minimizes sharp edges and loose debris, lowering workplace hazards. Applications Scrap metal balers are widely used in: · Recycling facilities · Automotive salvage yards · Manufacturing pla...

Read More

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported