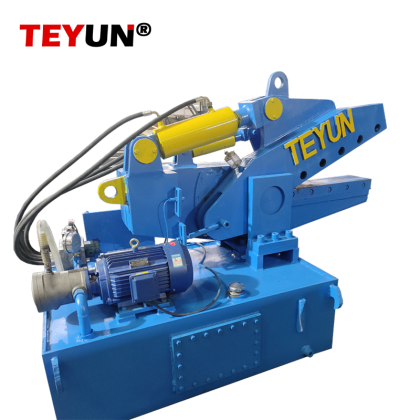

Gantry shear is a stationary hydraulic cutting machine for large, heavy, and dense scrap metal items too big for other equipment,such as demolition steel,industrial scrap, transportation scrap, white goods, and non-ferrous Metals. It uses strong shearing force to cut it into small pieces.

This is the most important step, as it determines the direction of all subsequent choices. Be sure to answer the following questions:

1. What material do you process?

Material: Is it ordinary carbon steel (A3 steel), stainless steel, aluminum alloy, copper, or mixed metal scrap? Different materials have different strengths and require different shear forces.

2. What is your processing capacity?

Average daily/monthly processing capacity (tons): This directly determines the size and efficiency of the equipment you need.

3. Nominal shear force (tons)

This is the most critical parameter. It indicates the maximum pressure the shears can generate.

Recommended selection: Choose based on the thickest and hardest materials you frequently process. It's better to choose a larger size than a smaller one. Insufficient shear force will lead to inefficiency, rapid blade wear, and even equipment damage. For processing heavy scrap steel and steel sections, a minimum capacity of 400 tons is recommended.

4. Feeding box size (length x width x height)

This determines how much material you can load at once and directly impacts work efficiency.

Width is particularly important as it determines the maximum width of material that can be handled.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported