In the demanding world of heavy metal fabrication, where precision, power, and reliability are non-negotiable, the metal gantry shearing machine stands as a titan. Moving beyond the capabilities of smaller hydraulic or mechanical shears, gantry shears offer a suite of formidable advantages that make them indispensable for serious industrial applications, particularly when processing large, thick plates. Here’s a closer look at their key strengths:

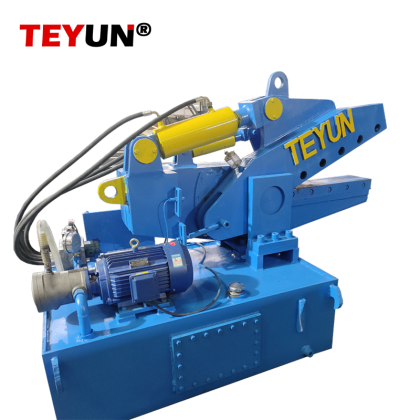

1. Unmatched Structural Rigidity and Power:

The defining feature – the massive overhead gantry beam – is the source of its greatest strength. This robust structure, supported at both ends, provides exceptional resistance to deflection and distortion during the cutting process. Unlike C-frame shears where the open side can allow ram flexing, the gantry's closed structure ensures force is applied uniformly across the entire cutting length. This inherent rigidity translates directly into the ability to shear incredibly thick and tough materials (often exceeding 1 inch/25mm in mild steel) with consistent force from edge to edge, minimizing distortion and achieving cleaner cuts even at maximum capacity.

2. Superior Cutting Precision and Quality:

Gantry shears leverage synchronized hydraulic cylinders mounted directly on the gantry beam to drive the upper blade. This setup allows for precise control over blade parallelism and cutting angle throughout the stroke. Combined with sophisticated CNC controls and advanced blade gap adjustment systems, operators achieve remarkably straight cuts with minimal burring and excellent edge squareness. This precision is critical for minimizing secondary operations (like grinding) and ensuring parts fit perfectly in subsequent fabrication stages, especially for large structural components.

3. Handling Massive Workpieces with Ease:

Designed with large, open beds and often featuring integrated roller conveyors or ball transfers, gantry shears excel at processing oversized plates that would be cumbersome or impossible on smaller machines. The gantry design inherently provides unobstructed access to the bed from three sides, simplifying loading, positioning, and unloading of heavy plates. This capability is vital for industries like shipbuilding, pressure vessel manufacturing, bridge construction, and heavy machinery, where large plate sizes are standard.

4. Enhanced Versatility Across Materials and Thicknesses:

While known for thick plate, modern gantry shears are highly versatile. They can efficiently shear a wide range of materials – from mild steel and stainless steel to aluminum and high-strength alloys – across a vast spectrum of thicknesses. Advanced models feature variable rake angles, allowing operators to optimize the cut for different materials and thicknesses, reducing required tonnage for thinner sheets and improving cut quality on thicker plates. This flexibility makes them a valuable asset in diverse fabrication shops.

5. High Productivity and Efficiency:

The combination of powerful shearing action, large bed capacity, efficient material handling systems (powered roller conveyors, hydraulic backgauges with CNC positioning), and fast cycle times translates into significant productivity gains. Operators can quickly set up jobs, accurately position large plates using CNC backgauges, and make multiple cuts rapidly. This efficiency is crucial for high-volume production runs or shops handling large quantities of plate stock.

6. Robust Safety Features:

Given the immense forces involved and the size of the workpieces, safety is paramount. Gantry shears incorporate comprehensive safety systems typically including:

Light Curtains: Creating an invisible barrier that stops the machine if breached.

Two-Hand Controls: Requiring simultaneous operator action to initiate a cut.

Robust Guards: Physically protecting the shear point and moving parts.

Emergency Stops: Strategically placed for immediate shutdown.

Blade Guards: Preventing access to sharp blades during operation or maintenance. The stable gantry structure itself also contributes to a safer operating environment by minimizing vibration and unexpected movement.

7. Durability and Long-Term Value:

Built for the long haul, gantry shears are constructed from heavy-duty materials with oversized components designed to withstand decades of punishing industrial use. The high initial investment is offset by exceptional longevity, minimal downtime (due to robust design), and consistently high output. They represent a significant asset that retains value and capability over a long operational lifespan.

The metal gantry shearing machine is not just a cutter; it's a cornerstone of heavy industrial fabrication. Its strengths – unparalleled rigidity for cutting thick plate, exceptional precision, massive workpiece handling capacity, material versatility, high productivity, integrated safety, and legendary durability – make it the go-to solution when standard shears fall short. For fabricators demanding the utmost in performance, reliability, and quality when processing large, heavy-gauge metal plate, the gantry shear remains an irreplaceable powerhouse, delivering the unyielding edge needed to conquer the toughest metalworking challenges.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported