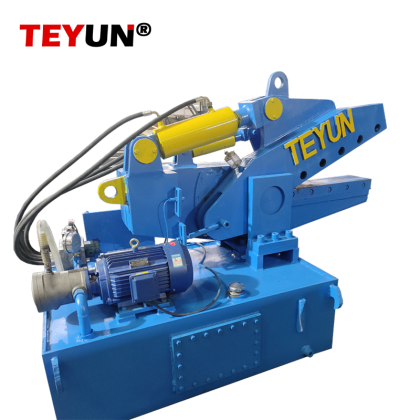

Horizontal baler is a heavy-duty industrial machine used to compress loose materials (such as cardboard, paper, plastics, textiles, or non-ferrous metal scraps) into dense, uniform bales for efficient handling, storage, and transportation. The machine operates primarily via a hydraulic system that drives a pressing head to compact material within a large chamber. Due to the significant forces involved and the presence of moving parts, strict adherence to safety procedures is paramount to prevent serious injury or equipment damage. The following outlines the essential safety protocol for its operation.

Safety Operating Procedures

I. Pre-operation Safety Inspection

Personal Protective Equipment (PPE)

Operators must wear the following: a safety helmet, cut-resistant gloves, safety glasses, and impact-resistant safety shoes.

Long hair must be secured under a cap. Clothing should be close-fitting; scarves, neckties, or garments with loose cuffs are strictly prohibited during operation.

Equipment Status Check

Visually inspect all hydraulic lines and connections for signs of damage, wear, or leakage.

Check electrical wiring, control switches, and emergency stop buttons to ensure they are intact and functional.

Verify that all mechanical/hydraulic locking devices on the packing chamber doors (both front and side) are in good working order and provide a secure lock.

Examine the interior of the compression chamber (feed hopper) and remove any foreign objects or residual hard material.

Confirm the hydraulic oil level is within the designated normal range.

Conduct a no-load test cycle. Observe all machine functions—main ram pressure, door opening/closing, and strapping mechanism—to ensure smooth operation without unusual noises.

II. Safety Regulations During Operation

Loading Stage

Ensure the machine is completely stopped with all moving parts in their neutral or home position.

Before opening any access door, confirm that both the main compression ram and the pre-compression ram (if equipped) are fully retracted to a safe position.

Never place hands, feet, or any part of the body inside the compression chamber.

Do not process flammable, explosive, corrosive, or excessively hard materials (e.g., untreated steel castings, large bearings) that could damage the equipment.

Distribute material as evenly as possible across the chamber to prevent one-sided loading. Strictly avoid overloading beyond the machine's rated capacity.

Any material longer than the feed hopper must be cut down or pre-treated before loading.

Door Closure & Compression Stage

After loading, the operator must visually confirm that all personnel are clear of the machine before closing and securing the chamber door.

Once closed, double-check that all doors are positively locked. This is a critical safety step.

During the compression cycle, no one is permitted to stand near the machine, especially directly in front of, beside, or behind the chamber. Personnel must remain outside the marked safety line in the designated control area.

Monitor the pressure gauge closely. Operation under sustained overpressure conditions is strictly prohibited.

Bundling & Bale Ejection Stage

Strapping may only begin after the main ram has completed its compression stroke, come to a full stop, and is maintaining pressure.

If manual assistance is needed for threading wire or strapping, it may only be done rapidly through a designated side safety access window, and only after the machine is fully stopped, pressure is maintained, and explicit permission is granted. Entering the compression chamber is strictly forbidden.

When ejecting the finished bale (by opening the door or activating the pusher), ensure no one is standing in front of the bale or in its ejection path.

Position ejected bales on a stable, level surface to prevent them from rolling or collapsing.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported