Metal Shredder: The Powerful Recycling Machine

December 24, 2025

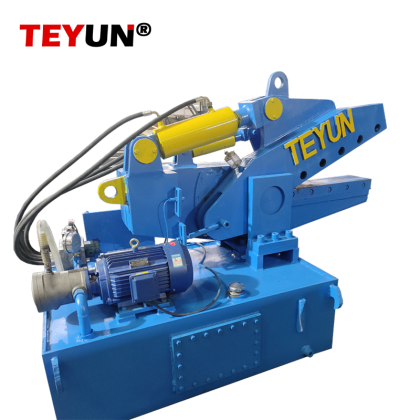

A metal shredder is an industrial machine designed to reduce large metal objects into smaller, manageable pieces for recycling and processing. These powerful machines play a crucial role in the metal recycling industry, transforming scrap metal into valuable raw materials that can be reused in manufacturing.

How Metal Shredders Work

Metal shredders operate using a series of rotating shafts equipped with cutting blades or hammers. When scrap metal enters the machine, these blades tear, cut, and shred the material through a combination of high torque and impact force. The process typically involves multiple stages: pre-shredding to break down large items, by fine shredding to achieve the desired particle size. Most modern shredders feature hydraulic systems that can generate immense pressure, allowing them to process everything from car bodies and appliances to construction materials and industrial waste.

Types of Metal Shredders

There are several types of metal shredders designed for different applications. Horizontal shaft shredders are common for processing large volumes of mixed scrap, while vertical shaft shredders are often used for specific materials like aluminum cans or electronic waste. Shear shredders use scissor-like cutting action for clean cuts, and hammer mills employ swinging hammers to pulverize materials. The choice of shredder depends on factors such as the type of metal, desired output size, and production capacity requirements.

Applications and Benefits

Metal shredders are essential in scrap yards, recycling facilities, and manufacturing plants. They prepare materials for further processing, such as magnetic separation to remove ferrous metals or eddy current separation for non-ferrous metals. The shredded material can be melted down and reformed into new products, significantly reducing the need for virgin materials and lowering energy consumption. This process helps conserve natural resources, reduce landfill waste, and minimize the environmental impact of metal production.

Key Features and Safety

Modern metal shredders incorporate advanced safety features, including emergency stop systems, overload protection, and automatic reversal mechanisms to prevent jams. Many are equipped with monitoring systems that track performance metrics and detect potential issues before they cause downtime. The efficiency of these machines continues to improve with technological advancements, making metal recycling more cost-effective and environmentally sustainable than ever before.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported