Tires shredder:Realize recycling of resources

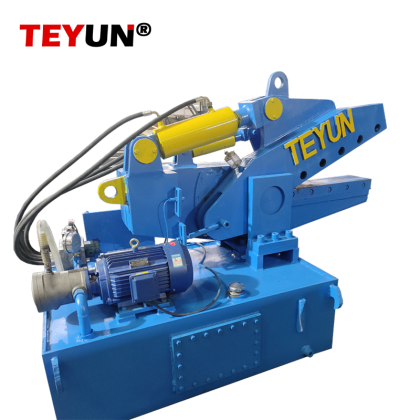

The tires shredder is a mechanical equipment that specializes in shredding waste tires. Using the shearing principle, the entire waste tire can be shredded into 5-8cm rubber pieces for later crushing and reuse or direct use. The shredder designed by TEYUN has the advantages of uniform discharging, high efficiency, large output, and reliable performance, and can be widely used in the waste recycling industry. The waste tires shredder can effectively convert waste tires into valuable resources. Waste tires contain a large amount of rubber, fiber, steel wire and other components, which can be processed by shredders and converted into raw materials that can be used to manufacture various products. For example, rubber particles can be used to make rubber floor tiles, rubber runways, rubber pipes and other products; fibers can be used to make recycled fiber materials; steel wire can be used to make steel wire ropes, steel wire mesh and other products. The market demand for these products is large, so the application of waste tire shredders can achieve effective utilization of resources and increase the added value of resources. Secondly, the application of waste tires shredder helps reduce environmental pollution. Waste tires are a kind of solid waste. If they are discarded directly without treatment, they will cause pollution to the environment. The application of waste tire shredder can convert waste tires into valuable resources and reduce environmental pollution. At the same time, the noise and vibration generated during the operation of the waste tire shredder are also small and will not have a negative impact on the surrounding environment. Finally, the application of waste tire shredder has economic benefits. Although the investment cost of a waste tire shredder is high, its operating costs are low and the payback period is short. Through the processing of waste tire shredder, waste tires can be converted into valuable resources, which can be used to manufacture various products, thus bringing economic benefits. In addition, with the improvement of environmental awareness and the promotion of resource recycling policies, the market demand for waste tire shredders is also increasing, so its application has broad market prospects.

Read More

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported