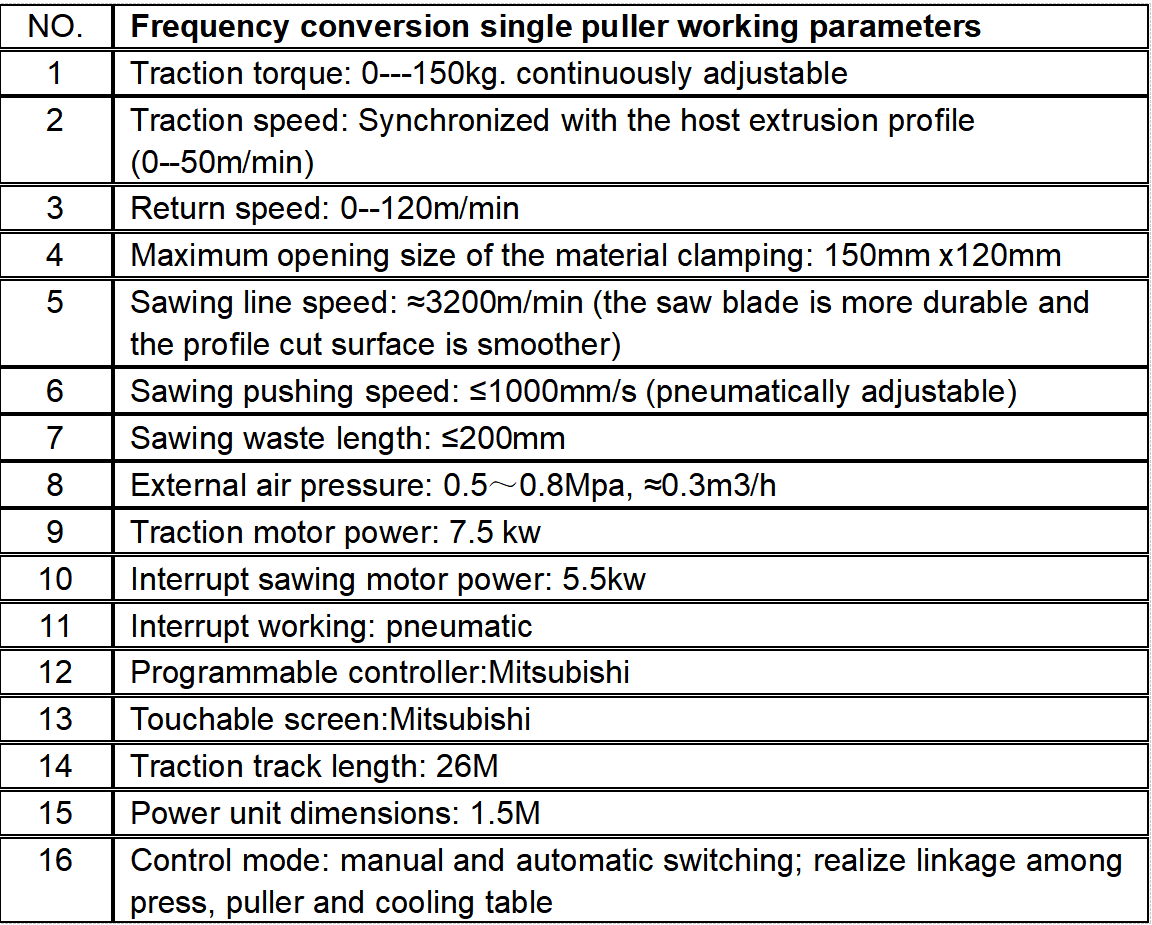

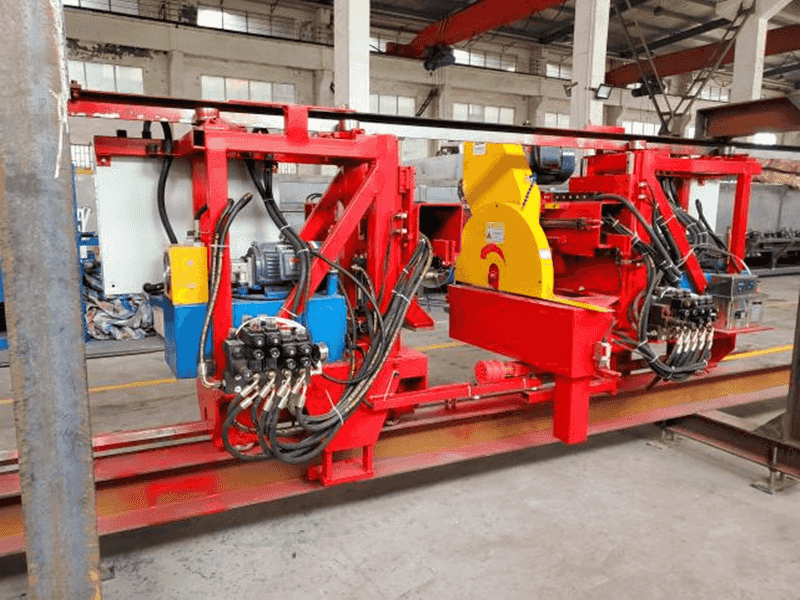

Aluminum Extrusion Single Puller(150kg)

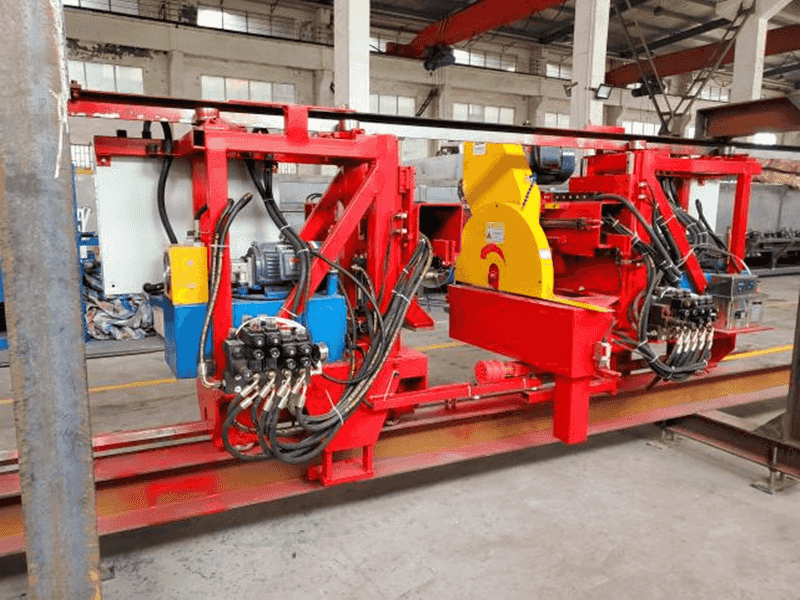

The aluminum extrusion single puller, also known as a caterpillar puller or traction machine, is a critical component in the aluminum extrusion process. It is specifically designed to extract the aluminum profiles or extrusions from the die after they are formed. The aluminum extrusion single puller is an essential machine used in the extrusion extrusion line to smoothly and accurately pull the aluminum profiles from the die, ensuring the production of high-quality and precisely shaped extruded products.

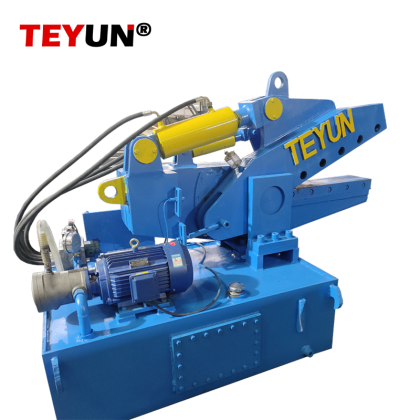

The single puller consists of a series of gripping or clamping mechanisms, usually made of rubber or similar materials, which move at a controlled speed. These clamps grip onto the aluminum extrusion as it emerges from the die, applying a precise amount of pulling force to guide it through the entire extrusion process.

The primary function of the single puller is to maintain a constant and uniform speed of the aluminum extrusion, preventing any deformation or damage during the process. It ensures that the profile remains straight and accurate while being carefully pulled through various cooling and shaping zones.

The speed of the single puller can be adjusted according to the properties of the extrusion, allowing for optimal control during the manufacturing process. The pulling force can also be regulated to accommodate different extrusion sizes and geometries.

Furthermore, the extrusion puller may incorporate additional features such as sensors, monitoring systems, and feedback mechanisms to ensure precise control over the pulling process. These features help maintain consistent product quality and prevent any deviation from the desired specifications.

-

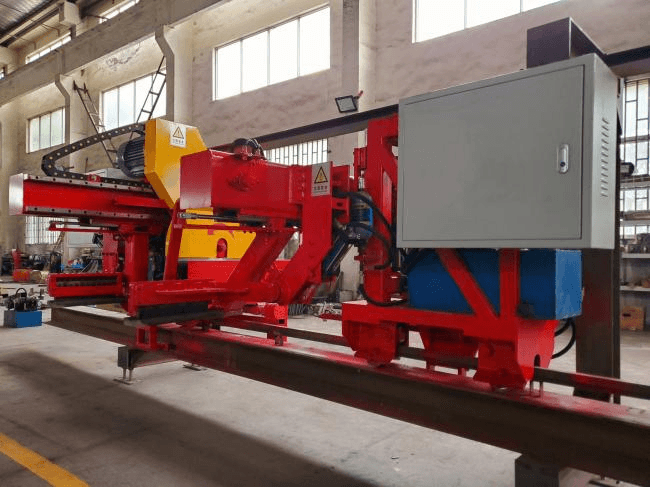

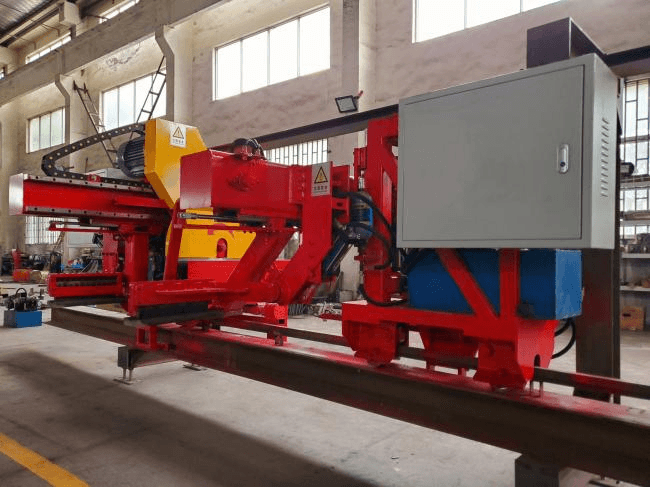

The aluminum extrusion pulleris possible to set the appropriate traction force to play cool with various models and profiles.

-

The selected traction force can be added stably and automatically to extrude profiles at different speeds, and the required traction force is determined by the section and type of the extruded profile

-

The traction speed can be synchronized with the extrusion speed of the extruded profile, and the jaws of the tractor are equipped with vertical clamps, which can clamp the extruded material on the plane during extrusion.

-

The jaws and clamps can loosen the extruded material and quickly return to the extruder surface, and the time required for the return is completed within the time when the extruder does not move.

-

It can extrude straight, neat, no bending and twisting and uniform length under the condition of a large number of operations in one machine, and improve the yield.

The whole line of the aluminum extrusion line consists of the aluminum extrusion main press, the puller, the automatic cooling table, the heating furance, the mold oven, the aging furance.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported