Why many customers use briquetting machines?

June 05, 2024

In the metal recycling process, shredding is often the first step. Depending on the composition and shape of the metal scrap, it is sometimes necessary to shred the residual metal before briquetting. This results in a homogeneous throughput size which are ideal for further processing. Shredding and further preparatory processing steps such as cleaning of the metal chips contribute significantly to the production of higher quality metal briquettes.

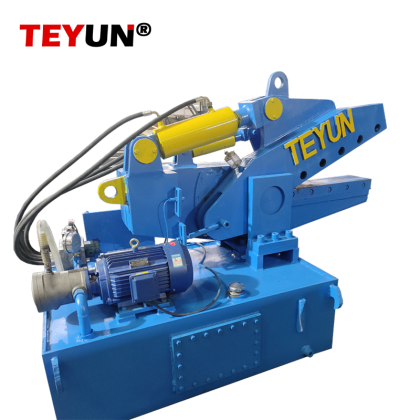

Briquetting machine has always been a hot-selling product of Teyun.Because metal briquettes offer numerous advantages: optimized storage and more efficient transportation through volume reduction. The briquetting process for metals also enables the recovery of expensive cooling lubricants, residual oils and emulsions, which are then fed back into the cooling or lubrication circuit. The resulting metal briquettes can be smelted down directly, whereby they sink down in the melting process and thus melt with less slag formation and burn-off.

In a short word, advantages of briquetting machine:

1. Direct and efficient melting down of the metal briquettes with significantly less burn-up

2. Volume reduction of up to 90% of the starting material

3. High pressing pressure for high briquette density

4. Better residue handling

5. Minimized disposal costs

6. Reduction of transport and storage costs

7. User-friendly design

8. Maintenance friendly

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported