In the vast and intricate world of industrial manufacturing and recycling, the ability to precisely and efficiently cut metal is paramount. Among the various techniques employed, shearing stands out as a fundamental process, especially in the lifecycle of metal containers. From drums and barrels to cans and custom enclosures, metal container shearing is a procedure that combines brute force with engineered precision to dismantle, size, and prepare these ubiquitous objects for their next purpose.

At its core, shearing is a cutting action that utilizes two sharp, opposing blades to fracture metal along a straight line. Imagine a common pair of scissors, but on an industrial scale capable of handling the toughness of steel, aluminum, or tinplate. The process does not involve melting or burning through the material; instead, it applies immense force to induce a controlled rupture. The metal container is placed between an upper blade, often angled (known as the rake), and a lower, stationary blade. As the upper blade descends, it first deforms and then cleanly fractures the metal, separating it into distinct pieces. This method is highly valued for its speed, clean edges, and energy efficiency compared to thermal cutting processes like plasma or laser cutting, which consume significantly more power.

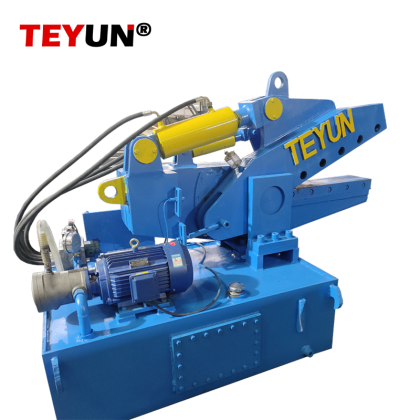

The shearing process for a metal container typically follows a logical sequence. First, the container must be prepared. This often involves ensuring it is empty, cleaned of any hazardous residues, and, if necessary, de-lidded. Safety is a non-negotiable priority. The container is then fed into the shear, either manually for smaller operations or via automated conveyor systems in high-volume recycling plants. The machine's hydraulic or mechanical system actuates the blade, performing the cut. For larger containers like 55-gallon drums, a guillotine-style shear is common, slicing the entire drum in half with a single, powerful stroke. For processing scrap cans, a massive alligator shear might be used, with its hinged jaw chomping down repeatedly to cut multiple containers into manageable fragments.

Several key parameters dictate the success of the shearing operation. The clearance between the upper and lower blades is critical. Too little clearance causes excessive wear and requires more force, while too much results in a deformed, burred edge. The rake angle of the upper blade helps to reduce the required force by distributing the cut over a longer stroke. Furthermore, the speed of the cut and the sharpness of the blades directly impact the quality of the finished edge and the overall efficiency of the operation. A well-maintained shear produces a clean cut with minimal deformation, whereas a dull blade will mash and tear the metal.

The applications of metal container shearing are extensive. In the recycling industry, it is the first step in size reduction, transforming bulky drums and cans into compact, uniform scraps that are easier to transport, sort, and melt down. In manufacturing, shearing is used to trim excess material from newly formed containers or to cut sheet metal to the correct size before it is formed into a container. Even in hazardous waste management, specially designed shears are used to safely open and dismantle contaminated containers for proper disposal and decontamination.

In conclusion, metal container shearing is far more than simple cutting. It is a refined mechanical process that plays a vital role in the circular economy, turning end-of-life containers into valuable raw material and supporting efficient manufacturing. Its blend of simplicity, power, and precision makes it an indispensable technology, quietly underpinning the lifecycle of the metal packages that fuel our modern world.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported