The Application of Tiger Shears in the Scrap Recycling Industry

March 05, 2025

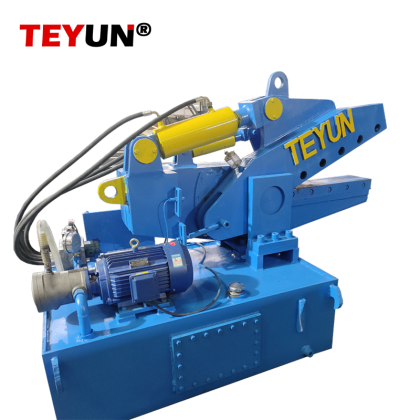

Tiger shears are a vital piece of equipment in the scrap recycling industry, renowned for their strength, precision, and efficiency in processing metal waste. These hydraulic cutting machines are specifically designed to handle heavy-duty tasks, making them ideal for cutting and reducing large volumes of scrap metal, such as steel beams, pipes, and other bulky materials.

One of the primary uses of tiger shears is in the initial breakdown of scrap items. In recycling facilities, large metal objects need to be cut into smaller, more manageable pieces. Tiger shears excel at this task, providing clean and efficient cuts that prepare the material for further processing, such as shredding or melting. This step is crucial for optimizing the recycling process and ensuring that materials can be easily transported and fed into downstream equipment.

Another key advantage of tiger shears is their versatility. They can handle a wide range of materials, including thick metal plates, rebar, and mixed scrap, making them suitable for diverse recycling operations. Their hydraulic systems deliver consistent power, enabling them to perform reliably even under demanding conditions. This reduces downtime and enhances overall productivity in scrap yards.

In conclusion, tiger shears are an indispensable tool in the scrap recycling industry. Their ability to efficiently cut and process large metal waste items contributes significantly to the streamlining of recycling operations, making them a cornerstone of modern scrap management.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported