Metal Briquetting Machines: Revolutionizing Recycling and Waste Management

March 12, 2025

Introduction

In industries ranging from automotive manufacturing to metalworking, the generation of metal scrap—such as chips, shavings, and turnings—is inevitable. Disposing of this waste efficiently poses significant challenges. Enter the metal briquetting machine, a pivotal innovation transforming scrap management by converting loose metal residues into compact, recyclable briquettes. This article explores the functionality, benefits, and applications of these machines, underscoring their role in promoting sustainability and operational efficiency.

What is a Metal Briquetting Machine?

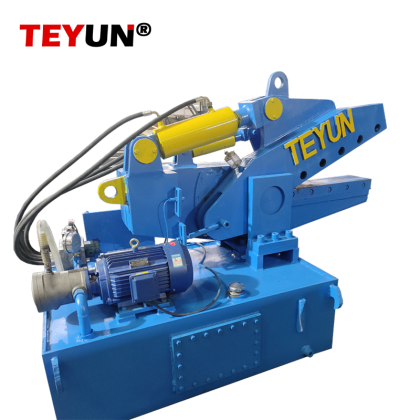

A metal briquetting machine is a robust industrial device designed to compress loose metal waste into dense, uniform briquettes. Utilizing hydraulic or mechanical systems, these machines apply extreme pressure to materials like steel, aluminum, copper, and brass, rendering them into portable blocks. This process not only facilitates easier handling but also enhances the value of scrap by making it suitable for direct reuse in manufacturing.

How Does It Work?

1. Feeding: Metal scraps are fed into the machine manually or via automated conveyors. Pre-processing may involve shredding to ensure uniform size.

2. Compression: A hydraulic ram exerts immense pressure (often hundreds of tons), compacting the metal into a solid briquette. Binding agents are occasionally added to improve cohesion.

3. Ejection: The newly formed briquette is ejected, ready for storage, transport, or melting in furnaces.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported