The UBC Aluminum Cans Paint Removing Line is a specialized system designed to strip surface coatings from used beverage cans (UBCs) before smelting, ensuring high-purity aluminum recovery.

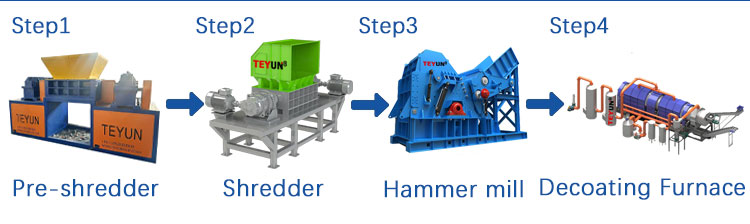

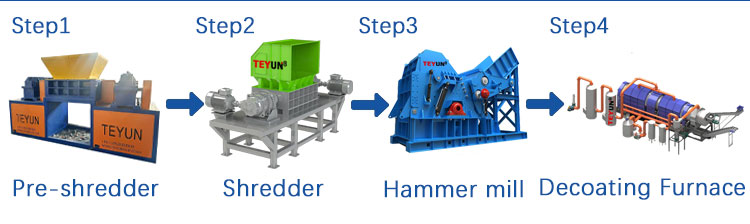

Process Workflow

1.Pre-Shredding: Packed UBCs are torn apart and shredded into small pieces (20-50mm) using a hammer mill, increasing surface area for efficient paint removal.

2.Thermal Decoating: Shredded material enters a continuous decoating furnace, where high temperatures (500-600°C) pyrolyze 99% of paints and coatings without oxidizing the aluminum.

3.Emission Control: Volatile organic compounds (VOCs) are treated via afterburners and scrubbers, meeting environmental standards.

Key Features

1.High Capacity: Models range from 500kg/h to 1500kg/h (e.g., DT-2000 with 61.3KW power).

2.Energy Efficiency: Indirect heating preserves aluminum yield (>97%).

3.Versatility: Also processes e-waste, separating metals from plastics via pyrolysis.

Key Advantages

1.High Efficiency: Removes 99% coatings with continuous operation (500-1500kg/h capacity).

2.Energy Saving: Indirect heating reduces oxidation, preserving 97%+ aluminum yield.

3.Eco-Friendly: Integrated VOC treatment (scrubbers/afterburners) meets emission standards.

4.Cost-Effective: Clean flakes cut smelting costs by reducing slag and flux usage.

5.Durable Design: Alloy-cast parts and premium burners ensure long-term reliability.

6.Versatile: Processes both UBCs and e-waste (metal-plastic separation).

This line combines high efficiency, low operational costs, and eco-friendly design, making it ideal for modern recycling plants.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported