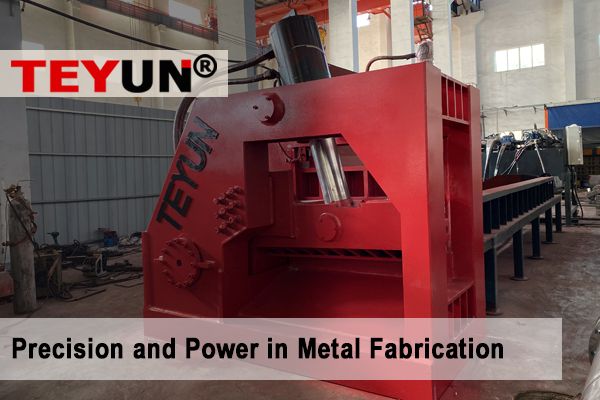

The alligator shear, named for its resemblance to the jaws of an alligator, is a heavy-duty mechanical tool widely used in the metal recycling and fabrication industries. This robust equipment is designed to cut through various ferrous and non-ferrous metals with high efficiency and precision, making it indispensable in scrap metal handling and production line operations. The core structure of an alligator shear consists of a fixed lower jaw and a movable upper jaw, powered by either hydraulic or mechanical systems. The hydraulic model, more common in modern applications, delivers a powerful cutting force—ranging from several tons to hundreds of tons—enabling it to shear thick metal plates, rods, pipes, and even bulky scrap components. Unlike other cutting tools, its jaw design allows for gradual and controlled cutting, which reduces material deformation and ensures clean, uniform cuts. In metal recycling yards, alligator shears play a crucial role in reducing the size of scrap metal, facilitating transportation and melting processes. They efficiently process end-of-life machinery parts, automotive components, and construction debris, transforming waste into reusable raw materials. In manufacturing plants, these shears are used for precision cutting of metal blanks, preparing materials for further shaping, welding, or assembly. Safety is a key priority when operating alligator shears. Operators must adhere to strict guidelines, including wearing protective gear and ensuring the work area is clear of obstacles. Modern models are equipped with safety features such as emergency stop buttons and interlock systems to prevent accidents. With their durability, versatility, and high performance, alligator shears remain a cornerstone tool in metal processing. They not only enhance work efficiency but also promote sustainable waste management, contributing to the circular economy within the metal industry.

We are online 7*24 hours to answer all your questions

-

Email : info@njteyun.com

Skype : sicily@njteyun.com

-

Tel : +86 13952083908

Whatsapp : +86 13952083908

-

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported