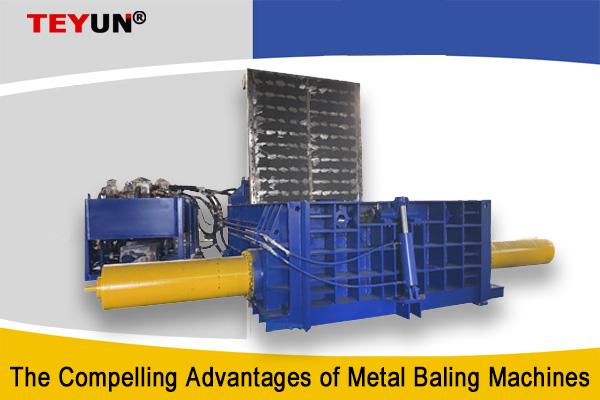

The horizontal baler stands as a cornerstone equipment within the waste management and recycling sector. Its work principle involves using hydraulic power to compress materials. When materials are fed into the baler, a hydraulic cylinder exerts immense pressure, gradually squeezing the materials together. As the pressure builds up, the materials are compacted into tightly packed bales. Engineered to compress an array of materials, including cardboard, paper, plastics, and even metals, into tightly packed bales, it dramatically diminishes waste volume. This reduction enhances the efficiency and cost-effectiveness of both storage and transportation processes. A primary benefit of horizontal balers lies in their remarkable versatility. They are capable of processing a diverse spectrum of materials, effortlessly adjusting to varying sizes and shapes. This adaptability renders them suitable for a multitude of industries, spanning from manufacturing to retail operations. Furthermore, horizontal balers are renowned for their impressive compression ratios, guaranteeing that the bales they produce are both dense and stable. This not only conserves valuable space but also significantly reduces the likelihood of bales disintegrating during handling and transportation. After each day's work is completed, it's the best time for maintenance: Thorough Cleaning: Remove any remaining paper scraps and debris from the hopper. Clean dust and oil from the pusher head, compression chamber, and bale outlet. Clean the equipment surface, keeping it clean overall. Inspect Key Components: Blades and Seals: Check the sealing strips on the compression chamber door for damage. Replace any damaged strips immediately to prevent leakage. Check the sharpness of the cutter. Chain/Wire Rope: For equipment using chains or wire ropes for threading, check their wear and tension, and add appropriate amounts of lubricating oil. Lubrication: Add the specified grease or lubricating oil to all lubrication points (such as guide rails, sliders, bearing housings, etc.) according to the equipment manual. Hydraulic System: After shutting down, check again for any leaks. Clean the area around the oil tank filler neck to prevent impurities from entering. In essence, the horizontal baler assumes a critical role in contemporary waste management strategies. Its efficiency, adaptability, and superior compression abilities render it an indispensable tool for businesses seeking to optimize their waste disposal and recycling workflows.

We are online 7*24 hours to answer all your questions

-

Email : info@njteyun.com

Skype : sicily@njteyun.com

-

Tel : +86 13952083908

Whatsapp : +86 13952083908

-

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported